Therefore, changing the rams can be necessary when switching to a different-diameter drill pipe or closing in a well with drill collars or casing (or other equipment) within the preventer stack. They are designed for sealing around a specific diameter of the pipe.

Pipe rams have a semicircular groove that enables sealing around the pipe. Sealing is achieved between the upper surface of the ram and the preventer body and between the sealing surfaces of the ram. As a backup measure, they can also be manually closed (Fig. They are closed by hydraulic pressure, which forces the set of rams together from both sides. Rams are found on most BOP blowout preventers stacks, except in some low-pressure applications. For this reason, it is common not to test annular preventers as often as ram-type preventers.

In particular, closing over an empty hole has an adverse effect on the sealing element. Frequent closing and opening of the sealing element will significantly shorten its life. The circular wedge then forces the sealing element toward the inside. Hydraulic pressure is applied to the low side of a wedge-shaped piston. The operating principle of this type of preventer is simple. Drilling mud or water can be used for lubrication. Still, it is necessary to lubricate the pipe while stripping it into the well. The pressure can also be adjusted to ease the passage of the tubular while stripping into the well by reducing friction. Operating pressure is generally lower than that used for ram-type preventers because the piston area is far larger. Because of its variable diameter, it also allows tool joints to pass when the pipe is being lowered into the hole while surface pressure is present, an operation called stripping (check also well control stripping procedure) (overcoming the pressure area forces with the pipe weight) or snubbing (forcing the pipe into the hole because the weight is not enough to overcome the pressure area forces) (Fig.6). This means that it can also seal around kelly (hexagonal shapes are better than square shapes).

This type of preventer is able to seal around any object with a circular (or nearly circular) cross-section as well as over an empty hole. BOP Blowout Preventers Types Annular Preventers Type

#Ram pressure classes full#

Even after setting multiple casings (with each casing head adding to the total height of the equipment), it still must be possible to accommodate the full preventer stack. The inclusion of a full-bore drilling spool makes it possible to connect the kill and choke lines (Adams 1979b, 1980a).Īn important consideration for the design of the BOP blowout preventer stack arrangement is the space it occupies under the rig.

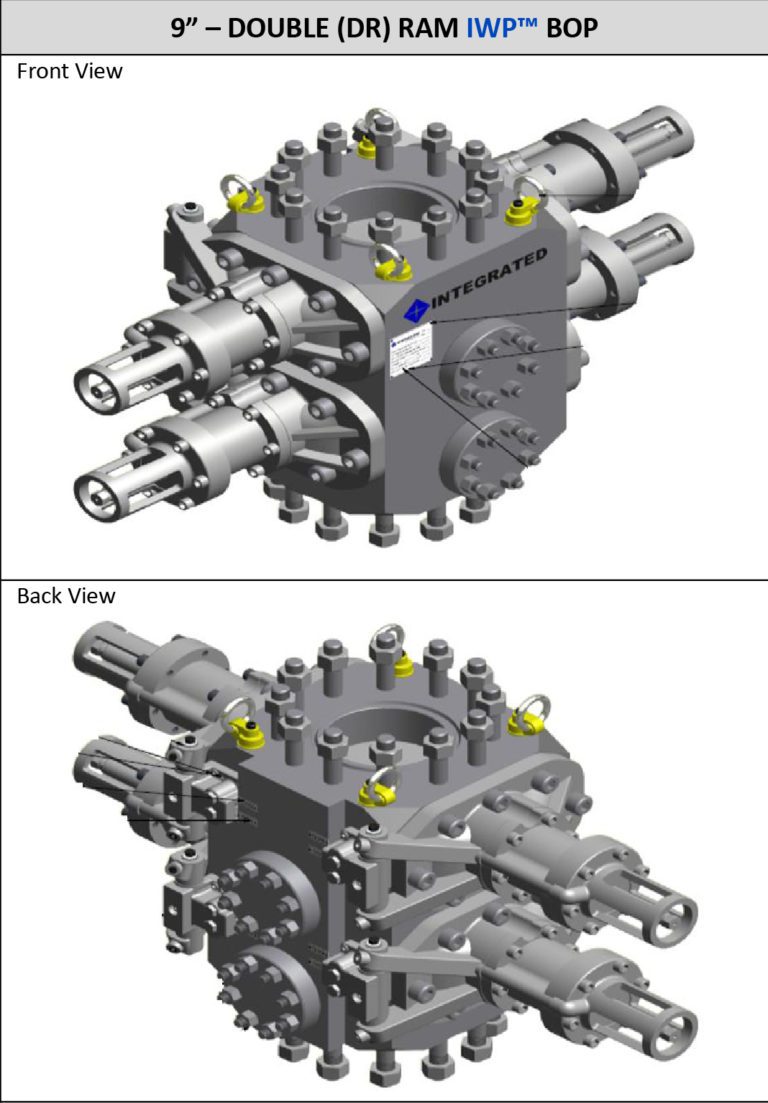

A preventer stack normally consists of an annular BOP preventer on top, followed by one or more (typically up to three) ram-type preventers (Fig.1). API Codes For BOP Stack ComponentsĪs we mentioned, blowout preventer stacks are rated to 2000, 3,000, 5,000, 10,000, or 15,000 psi.

0 kommentar(er)

0 kommentar(er)